Our Service to You

In these industries, if something should go wrong the consequences can be severe – projects can be put on hold indefinitely, people’s lives are put at risk, and precious time, money and resources can be squandered. URF’s job is to make sure that does not happen.

With vast knowledge and experience to its name, URF understands the demands and challenges that companies face today. What’s more, clients return time after time, clearly illustrating the success of URF’s services.

The services the company provides are focused on maintaining the client’s reputation within their industry and ensuring the equipment fitted on site is 100 per cent fit for purpose, verifying all the necessary documentation in the process.

URF’s experts specialise in the inspection and quality control of super duplex tubing – which is now common among oil and gas companies such as Technip, SS7, Aker Solution, Total, BP, Shell, Talisman and many more.

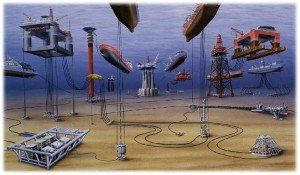

The company is also vastly experienced in examining equipment including umbilical fabrication; module and topside fabrication; overland pipelines and flowlines; valve inspection; welding and coating inspection; and compressor and power stations.

With inspectors based at leading engineering and petrochemical companies around the world, URF can inspect, test, review and sign-off a wide range of fabrications. The company carries qualifications and standards, which along with its unblemished track record with customers, is a clear indication of the quality services URF delivers.

New paragraph

Welding & NDE

- Welding Inspection Duties

- witnessing of associated laboratory testing – WPQR / WPS and WQT in both carbon and Super/Hyper Duplex Stainless Steels

- Witness and verification of:

- Radiography,

- Ultrasonic’s (AUT),

- Eddy Current,

- Magnetic Particle Inspection

- Dye Penetrant Inspection

Topside Inspection & Witnessing

- Witness of Hydrostatic and Gas Pressure Testing

- Painting and Coating Inspection

- Ball / Needle Valve Inspection and Forgings

- Armouring Wire Inspection

- Valves

- Pipeline End Manifolds

- Pipeline End Terminations

- Topside Termination Units

- Electric & Fibre Optic Cable Manufacturing, Inspection and Terminations

- Witness Of camera inspections for the Umbilical, Riser and Flowline industry

- Umbilical Close out Activities

- Reel Fabrications/Reel Hardware

- Pull in/Hang Off (PIHO)

Subsea Hardware Inspection & Witness

- Umbilical Terminations Assemblies

- Stabplates

- Bend Stiffener Connector (Latching Mechanism).

- Bend Stiffeners

- Bend Restrictors

- Buoyancy Modules

- Steel Tube (Duplex)

- Uraducts

- Mudmats

- Subsea Termination Units

- Tronic Connectors

- Cobra Heads

- Seamless Tube

- Seamed SD Tube

Quality

- Audits

- Problem solving/resolution

Documentation

- ITP Reviews

- Quality Documentation Reviews

- MDRB review and approval